Wide Range of Models and Sizes

Purific solution has highly effective protective properties against an array of pathogens. The solution undergoes electrolysis in special electro-chemical cells in which the pH of the water is manipulated to be in a well-defined range. The active material is hypochlorous acid (HOCl) in a concentration range of 50-200 PPM and a pH range.

The system has the capability to choose the pH and active material concentration.

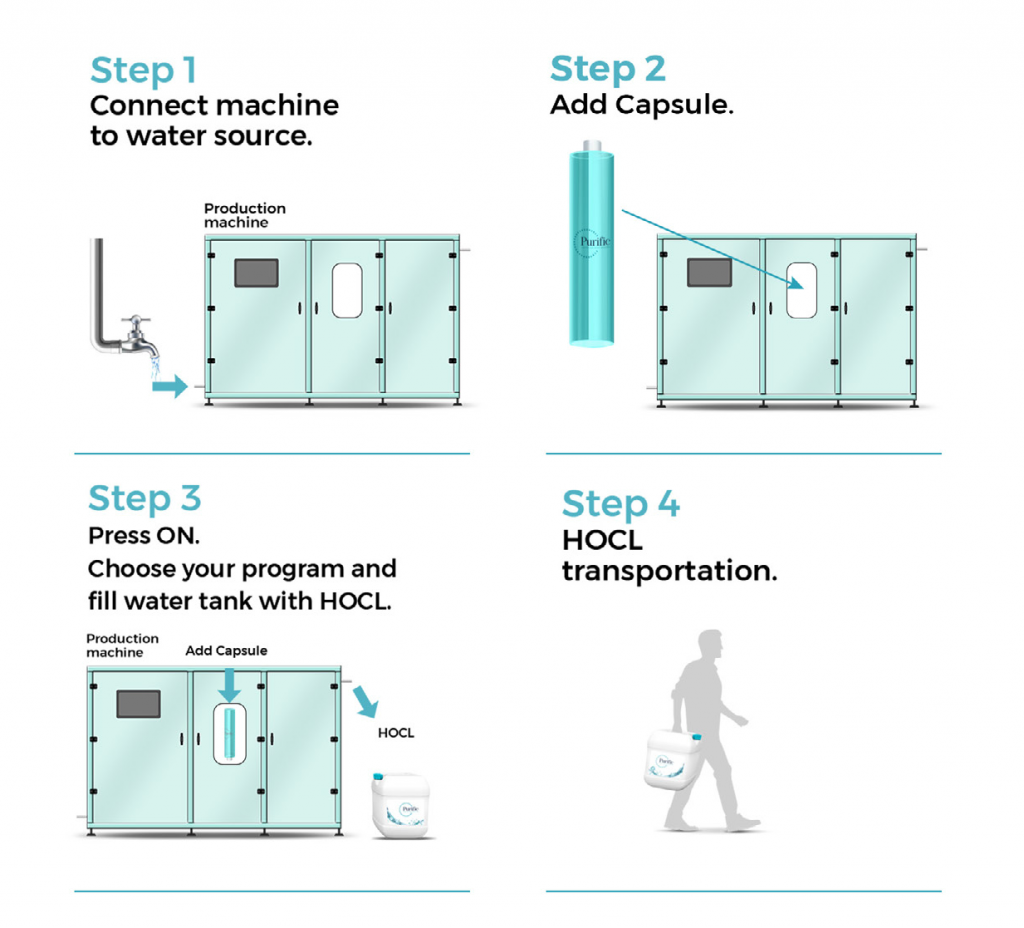

To produce Purific’s Electrolyzed Water, a production unit will need a water source connection and an Ionized Electrolyte solution capsule.

| Model | Production Volume | Dimensions (WxHxD) | ||

| EW 10 | 10 Liter/hour (200 PPM) / 40 Liter/hour (50 PPM) | 450x120x500 (mm) | ||

| 2.5 Gallon/hour (200 PPM) / 200 Liter/hour (50 PPM) | 17.7×4.5×19.7 (inch) | |||

| EW 50 | 50 Liter/hour (200 PPM) / 200 Liter/hour (50 PPM) | 450x120x500 (mm) | ||

| 12 Gallon/hour (200 PPM) / 50 Gallon/hour (50 PPM) | 17.7×4.5×19.7 (inch) |

Ideal for:

Clinics, Labs, Operation Rooms, Restaurant, Salons, Supermarkets, Schools, Offices, Supermarkets Theatres and more.

| EW 150 | 150 Liter/hour (200 PPM) / 600 Liter/hour (50 PPM) | 1600x1600x750 (mm) |

| 37.5 Gallon/hour (200 PPM) / 150 Gallon/hour (50 PPM) | 63x63x29.5 (inch) | |

| EW 250 | 250 Liter/hour (200 PPM) / 600 Liter/hour (50 PPM) | 1600x1600x750 (mm) |

| 62.5 Gallon/hour (200 PPM) / 250 Gallon/hour (50 PPM) | 63x63x29.5 (inch) |

Ideal for:

Hospitals, Airports, Train Stations, Hotels, Office Buildings, Stadiums, Malls, Food Factories and more.

| EW 500 | 500 Liter/hour (200 PPM) / 2000 Liter/hour (50 PPM) | 2400x1600x750 (mm) |

| 125 Gallon/hour (200 PPM) / 500 Gallon/hour (50 PPM) | 94.5x63x29.5 (inch) |

Ideal for:

Industrial Production

How it works

Capsule

What is the capsule?

The capsule is unique combination of saline solution when wisely being mixed with the feed water, makes the solution ready for right and optimal electrolysis process toward production of disinfectant solution.

Why using a capsule?

The production of efficient , accurate composition and highly pure disinfecant solution is an outcome of delicate combination of the feed solution, reactor design and system architecture. The capsule ensures that the system is fed with the ultimate feed solution coomposition with respect the system and reactor design.